ProVent

Ventilating underlay for floating floors

Leading the industry with innovative air quality and climate control systems. Engineered for efficiency, designed for sustainability.

Let your floor breathe

ProVent best features

Ventilation

Air movement under Provent is verified

Noise insulation

Good acoustic insulation for you and your neighbours

Full humudity protection

No additional vapor barier required

Floor heating systems

Recommended for use with water heating systems

What is ProVent?

ProVent’s ribbed underside creates a unique system of air channels. Humidity is extracted through these air channels, allowing the concrete subfloor to dry and keeping it dry. ProVent consists of a combination of closed-cell low-density polyethylene (LDPE) foam and a membrane of high-density polyethylene (HDPE) which are laminated together by heat. The material comes in rolls. The size of the air channels and the structure of foam are adjusted to ensure the flexibility and durability of material. A testing showed that ProVent didn’t change its original thickness even after 100 000 simulated footsteps while maintaining the ability to ventilate the underfloor area. Manufacturing of ProVent requires the use of selected polyethylene resin brands of high quality. This way we ensure the small size of tiny air cells and the fine cell structure everywhere in the foam.

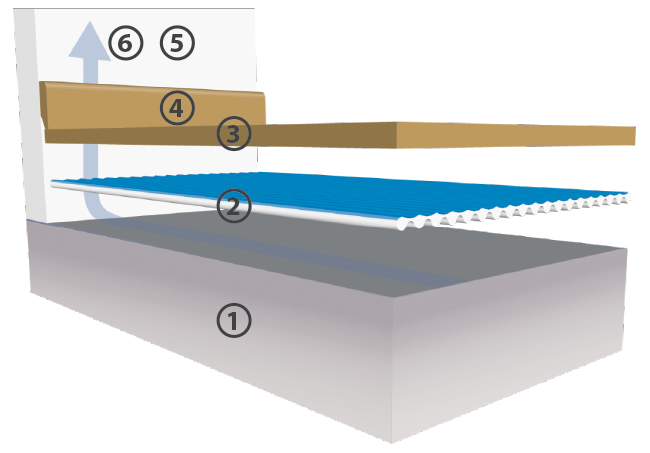

Explanation

- 1 CONCRETE SUBFLOOR

- 2 ProVent

- 3 PARQUET/LAMINATE FLOOR

- 4 SKIRTING BOARD

- 5 WALL

- 6 AIR EXCHANGE

Technical information

| Thickness | 2.3 mm | 3 mm |

|---|---|---|

| Reduction in walking noise (DIN 4563) | 22% | 22% |

| Impact sound improvment level (ISO 140/8) | 22 db | 22 db |

| Water permeabilty value (sd) (combined effect of ventilation feature and HDPE vapour barrier) | 100m | 100m |

| Thermal resistance R (m2K/W) | 0.040 | 0.070 |

ProVent best features

Ventilation

ProVent ventilates the subfloor due to the protected MicropumpingTM ventilation system. The profiled underneath surface forms the system of air channels which ensures the air exchange that eliminates water vapour from the underfloor area. Air channels create an open system between the air in the room and the air under ProVent. Due to the laws of physics the humid air goes out through the channels to be replaced by the dry air. Humidity in the area between subfloor and flooring material often leads to the formation of mould. Mould presents a huge problem not only to the building itself. The more important issue is the potential health hazard to humans due to possible allergic reactions and respiratory problems. Mould may cause more types of illnesses like immunotoxic and infection. ProVent is the first low cost system of self-ventilated flooring underlay that eliminates the conditions for development of mould. This way ProVent helps to create a healthy environment in your living area as well as in your office.

Noise insulation

Normal polyethylene foam underlay has got a ratio of impact noise reduction of 17 dB to 19 dB. For example, PEPI 2mm underlay provides an impact noise insulation of 19 dB. ProVent performs quite better with 22 dB. The better acoustic properties come from the special cell structure of the foam base and the profiled surface of underlay.

Full humidity protection

Underfloor ventilation feature improves considerably the level of protection that ProVent provides for the flooring material. When using ProVent you may install the flooring earlier than with conventional underlay. ProVent provides a full moisture protection of flooring and there is no need for any additional vapor barrier. ProVent fights the humidity at two levels: 1. Vapor protection properties of the material itself. The layer of closed-cell polyethylene foam in combination with HDPE membrane ensures a high ratio of the water vapor resistance. 2. MicropumpingTM ventilation system extracts water vapor from the underfloor. Due to the permanent drying there is no water condensate on the surface of concrete.

Floor heating systems

We recommend to use ProVent with water heating systems under most brands of laminated flooring up to the thickness of 15mm. ProVent is very useful in summer time when water heated floors switch off and the water in pipes gets cold creating an excess of humidity that leads to water condensate. ProVentTM ventilation system would eliminate it. Both 2.3mm and 3mm versions are good for the heated floors but especially the 2.3mm ProVent because the thermal resistance of it is less - 0.040 m²K/W or 0.4 togs. The 3mm version has got 0.070 m²K/W or 0.7 togs. ProVent may be used also with other systems of floor heating if they accept the use of floating floors.

APPLICATION AREA

ProVent was created especially for the use on concrete subfloors but it is good for most other applications with floating floors including over the water heated floors.

THICKNESS OF FLOORING

ProVent may be used under laminated and engineered floating floors with the thickness range of 6mm to 16mm. ProVent IS NOT suggested for the use with the flooring that requires underlays with the maximum of 2 mm thickness.

FAST & EASY INSTALLATION

ProVent underlay reduces dramatically the time of flooring installation. ProVent comes with an integrated extra vapour barrier. You can lay ProVent at one go unlike with a conventional underlay that requires the additional installation of the vapour barrier.

Installation guidelines

Important notes

!

Lay ProVent with the HDPE membrane up and the profiled/ribbed side down. The profiled side of ProVent should face the surface of concrete subfloor in order to enable the ventilation system.

!

A reminder THIS SIDE UP is printed on the HDPE membrane. No vapour barrier may be used under ProVent because it would close the air channels and stop the ventilation process.

1.

CLEAN properly the subfloor surface, following the instructions of the producer of parquet or laminate. ProVent provides a compensation of the micro-roughness in the floor base (maximum 2mm within a distance of 2m).

2.

LAY ProVent with the air channels to the direction of the laying of flooring panels. For better ventilation lay ProVent with air channels perpendicular to the longest size of the room.

3.

Lay the FIRST ROW of ProVent with the printed side up, the wavy side down and the HDPE overlap towards the wall. Leave about 1cm space to the wall. Cut off or turn up the HDPE overlap of the first row of ProVent.

4.

With the overlap of the NEXT ROW of ProVent cover the edge of previous row and spread it even. Make sure that there are no sharp objects on the surface of ProVent underlay to avoid damaging the HDPE film.

5.

LAY PARQUET OR LAMINATE according to the instructions of the producer of the respective product. We recommend to spread out only one row of ProVent at the time, then install the flooring and, after finishing the first section of floor, continue with the next ProVent row.

6.

OPTIONAL: create an air gap. The common practice of floor laying creates enough space for air exchange under ProVent. However you may wish to create even better conditions for the ventilation. It is enough to leave just a 2-3mm gap between the surface of parquet or laminate and the floor lath for better air exchange. There are two main ways to create the air gap (see in the drawing). You can leave the gap either between the flooring and the floor lath (option A) or between the floor lath and the wall (option B). See the drawing here.

Our Partners

Certificate of conformity1

Product complies with the requirements for the construction products.

Emission classification of building materials2

ProVent belongs to the low emission class M1

National technical approval in Germany3

ProVent may be used as a valid flooring underlay due to a low emission level and accepted fire class

Health and environmental assessment12

ProVent does not contain any restricted health and/or environmentally hazardous substances. Grade A, the best classification

Enviroment management certificate4

SIA „PEPI RER” maintains the Environment Management System according to ISO 14001

Recommendation from the Estonian Allergy Federation5

Right to use "Eesti Allergialiit tunnustab" (Recognised by Estonian Allergy Federation) marking on ProVent

Recommendation from the Latvian Asthma and Allergy Association6

Right to use a special marking on ProVent

Verification of the air movements under laminate parquet when ProVent is used7

ProVent „enables the air to move in the canals formed beneath the underlay” and „air moves beneath laminate parquet due to micro-pumping caused by walking”

Determination of concrete drying underneath underlays with air channels/ventilation gap. Test performed with ProVent8

ProVent creates an open system between the room air and the surface of the concrete. ProVent ensures permanent drying of concrete

Determination of the impact sound insulation with a 7 mm laminate flooring7

The reduction of impact sound pressure level (sound direction DOWN) ∆Lw = 20 dB

Determination of the impact sound insulation with a 14 mm parquet flooring9

The reduction of impact sound pressure level (sound direction DOWN) ∆Lw = 21 dB

Determination of the walking sound improvement with a 7mm laminate10

Relative difference of the loudnesses of the reference and the test flooring (sound direction UP): 4.6%

Determination of the walking sound improvement with a 14mm parquet flooring10

Relative difference of the loudnesses of the reference and the test flooring (sound direction UP): 8%

Effectiveness of floor coverings in reducing Impact Sound Transmission through concrete Floors, with 8mm laminate11

Established Increase in impact insulation class ∆IIC = 21.0 .Testing performed for the USA market

Impact Sound Transmission Test, with 8mm laminate11

Established normalized impact sound pressure level. Impact Insulation Class IIC (dB) = 50. Testing performed for the USA market.

Sound Transmission Loss Test, with 8mm laminate11

Established Sound Transmission Class STC (dB): 49 .Testing performed for the USA market

Determination of the water vapour permeability7

Water vapour transmission properties of ProVent established

Moisture performance research report7

ProVent „gives the flooring about the same protection against the rising moisture as the 0.2mm PE foil”

Determination of the thermal conductivity and the thermal resistance

ProVent may be used with the floor heating systems. The thermal resistance of ProVent is 0.070 (m²K)/W

Vertical deformation of an installed laminate flooring over ProVent8

Vertical movement of the flooring over ProVent has the same range as over 2mm PE-foam underlay (<0.5mm)

Determination of alternate vertical movements on the structure of ProVent underlay and joints of the parquet/laminate floor8

Performed with 18 brands of laminate and parquet flooring. ProVent did not loose its original thickness under 100,000 repetitive loadings and the movements did not damage the joints of sample flooring.

Determinate the change of appearance of laminate floor joints under the movement of a castor chair by using ProVent underlay8

Performed with a number of laminate and parquet brands. No detachment of layers, opening of joints nor crazing were found on samples.

Required load for a 0.5mm loss of thickness8

900kg/m2 according to DIN EN 826

LIST OF TESTING INSTITUTES

1 AS Inspecta Latvia, Inspecta Group Oy, Helsinki, Finland

2 Rakennustieto, Finnish Building Information Foundation RTS, Finland

3 Institut für Bautechnik DIBt,Germany

4 PEPI RER SIA, manufacturer

5 Estonian Allergy Federation

6 Latvian Asthma and Allergy Association

7 VTT Technical Research Centre of Finland

8 PEPI RER Quality Control Department

9 R&D Akustika SIA, Testing laboratory, Latvia

10 IHD, Entwicklungs- und Prüflabor Holztechnologie GmbH, Germany

11 NGC Testing Services, Acoustical Testing Laboratory, USA

12 SundaHus Miljödata, Sweden